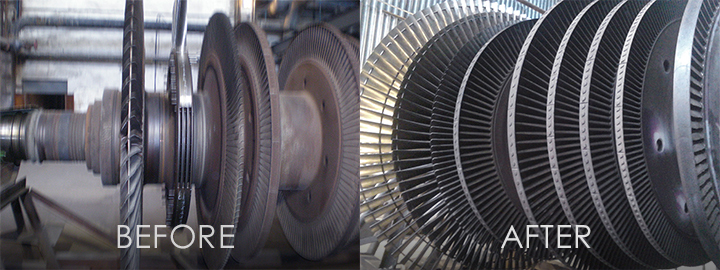

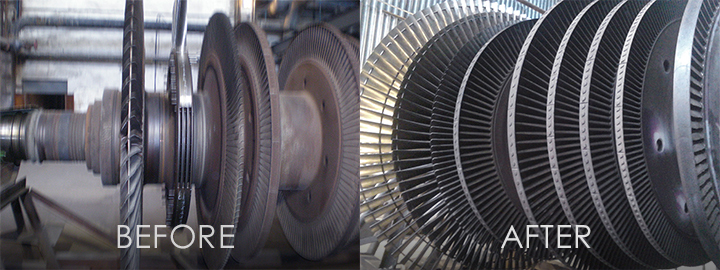

50MW - Lacing Wiring - Blade Replacement & Repair

Project Overview:

1. Number and Location of the Blades. Facing the nose, the sealing piece of the last stage blade is identified as blade No. 0, followed by No.1, 2, 3... in counter clockwise direction.

2. Blade Disassembly Technique.

a. Spray loosen agent at the whole second last stage blade;

b. Cut lacing wire, so that the blades become loose;

c. Pull out the pin with special tools and be careful not to hurt the wheel;

d. Identify which blade shall be removed at first, then pull it out with special tools;

e. Remove all the blades of the whole stage in turn.

3.Blade Manufacturing Technique

4. Blade Installation Technique

a. Clean the wheel disk’s slots for the installation of the new blades;

b. Grind the blade root so that the blade’s root contact surface can meet the standard;

c. After grinding the blade root, install them back in order and install the lacing wire;

d. Compress the blade with a special tool;

e. Check the pin hole;

f. Fit back the pin;

g. Hammer the rivet pin and expand the nail head to keep it tight;

h. Weld the lacing wires;

i. Inspection for acceptance.